20.03.20; Mar.2020

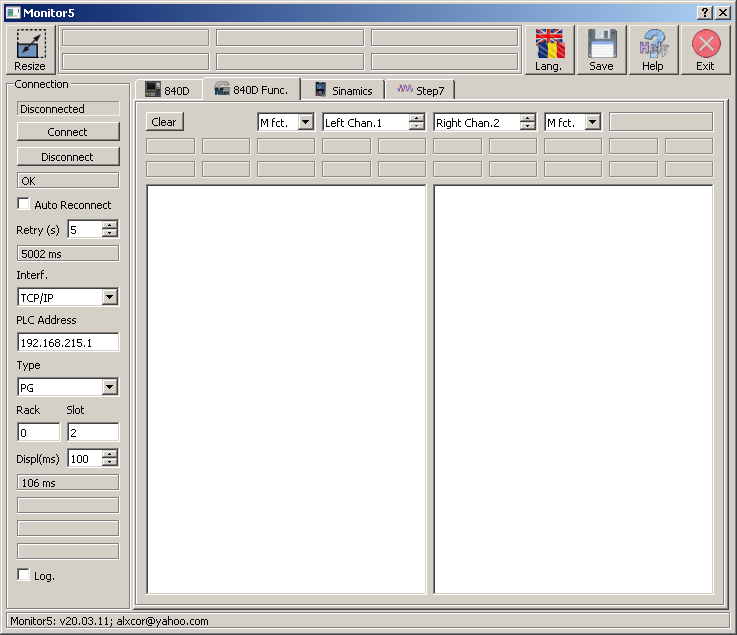

Monitor 5

help

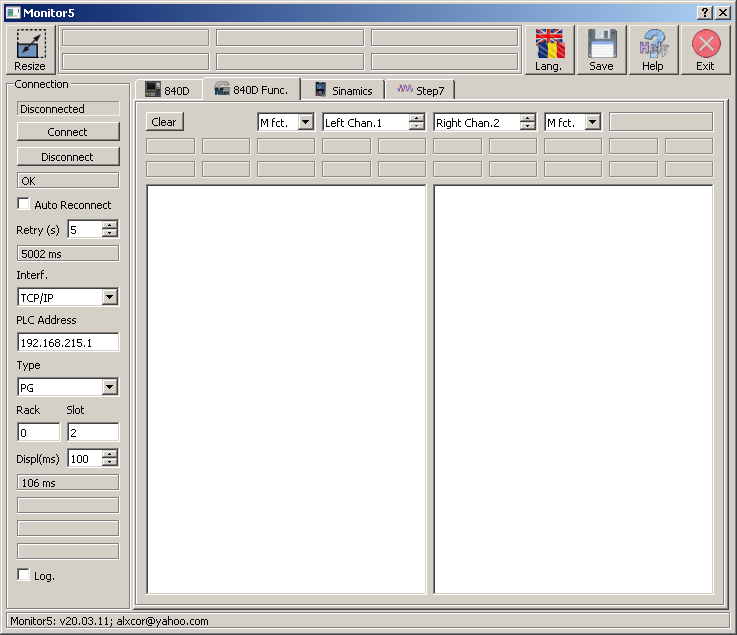

Area '840D Functions'

Monitor NC functions (NC to PLC):

- monitor and record all the M (Miscellaneous), S (Spindle Speed), T (Tool) functions, D (cutting edges for a tool) or H (as Integer or as Real) functions sent from a Part Program to PLC.

There are two windows so is possible to monitor simultaneous two types of functions (e.g. T and D functions) from the same Channel or from two different Channels of the NC.

M functions (NC to PLC):

M functions are commands, written in G Code, in the part program, but executed by the PLC.

Example: Start the cooling for the tool in main Spindle: the command is written in the part program (e.g. M07) but the valve for cooling liquid is controlled by PLC.

Using M functions is the most common way to transfer binary commands from NC to PLC.

Decoding M functions in the PLC:

With Sinumerik 840, there are 3 methods to decode the M functions in PLC.

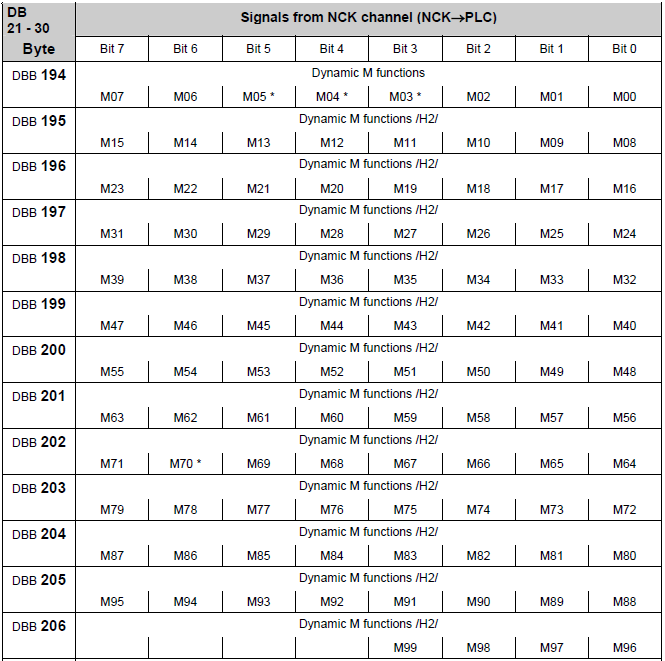

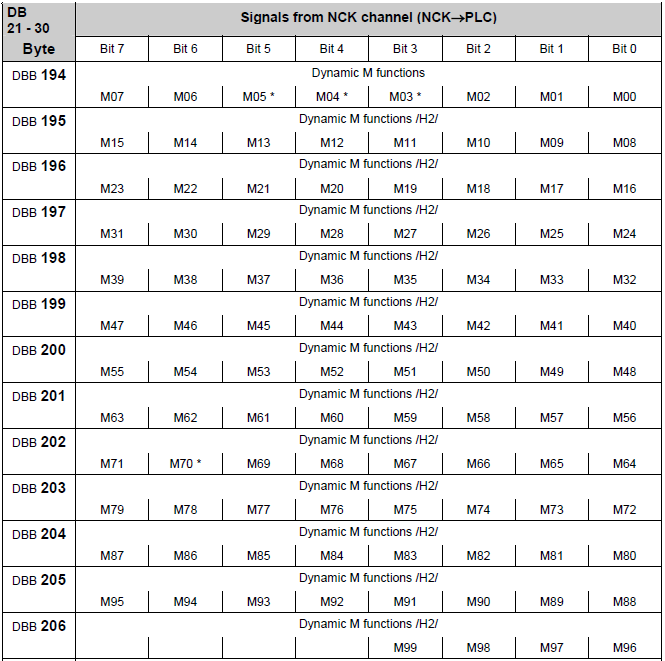

1. Direct decoding (Quick M functions)

The most simple method to decode M functions is to use the direct decode signals from 'Channel DB' in PLC.

Each bit is set for a single PLC cycle.

Only first 99 functions are decoded.

The M function index is not decoded.

A small calculator for the bit and a monitoring function is available in 'Area 840' of Monitor5 program.

2. Decoding using a List of Functions (DB75, DB76)

Another method for decoding M function in PLC is using a List of Functions.

This method was very popular in the '90s but is rarely used now.

Precondition:

Must be activated in OB100, in FB1, DB7 call:

CALL FB 1, DB7

...

ListMDecGrp := ___ //number of decoded function groups, max. 16 groups

...

Hint for service: If in OB100, in FB1 call you see ListMDecGrp > 0 and DB75 and DB76 are present in the PLC, this method is used to decode M functions for this machine.

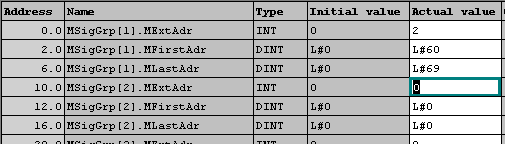

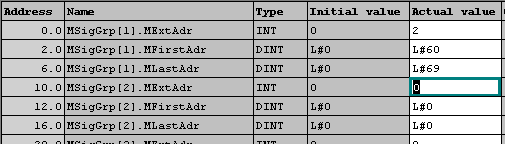

DB75 is created using a template from Sinumerik Toolbox.

The struncture is:

MSigGrp[1].MExtAdr INT //M function extension for Group 1

MSigGrp[1].MFirstAdr DINT //1st M function Number for Group 1

MSigGrp[1].MLastAdr DINT //last M function Number for Group 1

...

MSigGrp[n].MExtAdr INT //M function extension for Group n

MSigGrp[n].MFirstAdr DINT //1st M function Number for Group n

MSigGrp[n].MLastAdr DINT //last M function Number for Group n

Example:

In DB76 the bits will have the following meaning:

DBX0.0 M2 = 60

DBX0.1 M2 = 61

....

DBX0.7 M2 = 67

DBX1.0 M2 = 68

DBX1.1 M2 = 69

Bits in DB76 remain set. Their value must be reseted by the custom PLC program.

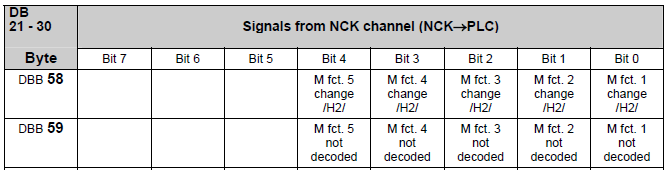

3. Scan the modified values

Another method for decoding M function in PLC is using a scan for 'modified' status of the functions.

This method is used also by Monitor5 program.

Into an NC block is possible to have a maximum of 5 calls for M functions.

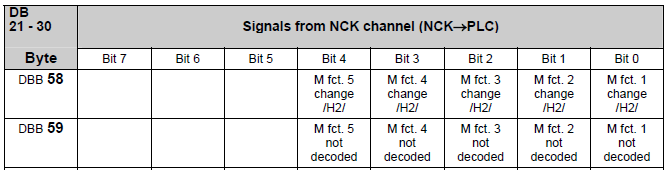

Eack time a block with M fct. call is running in NC, the following bits are set, for a single PLC cycle, in Channel DB in the PLC.

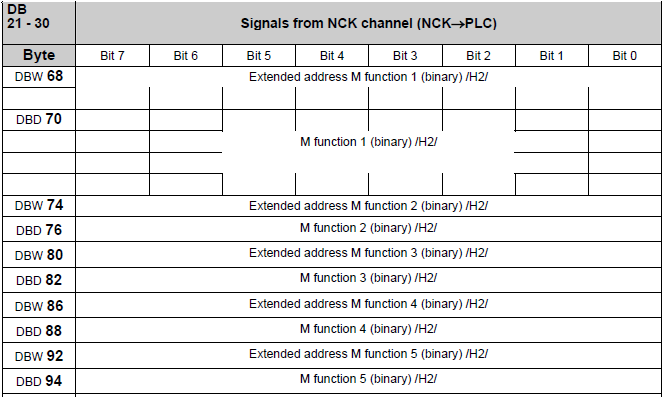

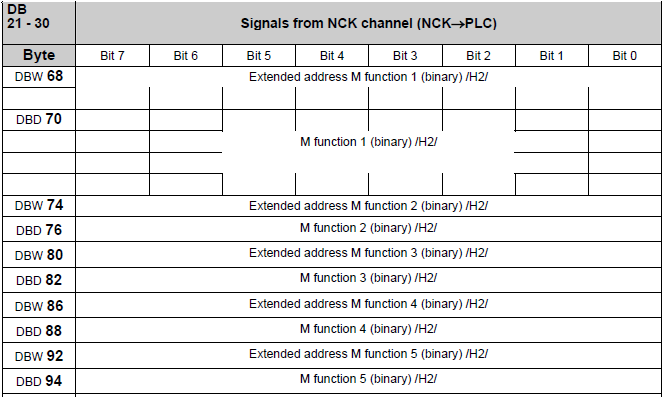

...and the function value is written in:

'Monitor5' is scanning the bits in DB2n.DBX 58.0 ... 58.4

If DB2n.DBX58.0 = 1 => read M function number from DBD70 and M fct. extension from DBW68

If DB2n.DBX58.1 = 1 => read M function number from DBD76 and M fct. extension from DBW74

If DB2n.DBX58.2 = 1 => read M function number from DBD82 and M fct. extension from DBW80

If DB2n.DBX58.3 = 1 => read M function number from DBD88 and M fct. extension from DBW86

If DB2n.DBX58.4 = 1 => read M function number from DBD94 and M fct. extension from DBW92